TO OPTIMIZE THE PERFORMANCE OF YOUR RENEWABLE ENERGY PRODUCTION PARKS, WE OFFER A RANGE OF SERVICES CONTRIBUTING TO IMPROVING THE PRODUCTIVITY OF YOUR ASSETS.

Our analyst engineers can perform scada analyses to remotely assess the underperformance of your wind farm, but also performance ratio and availability calculations for your photovoltaic power plants. Within the framework of the reception of your wind turbines do not hesitate to call on us to follow and validate the run tests making it possible to confirm the final acceptance.

You are aware that aerodynamic and mass imbalances cause underperformance and premature wear of major components. Our experts are able to measure these imbalances but also to support you in the stages of their resolution to assure flawless performance optimization.

MEASUREMENT & CORRECTION OF AERODYNAMIC BALANCE

Our methodology:

- Imbalance diagnosis by low frequency (LF) vibration measurements on 100% of turbines

- Adjustment of blade angles by photometry to remove aerodynamic imbalance on affected machines (around 30% of turbines)

Benefits:

Decrease in nacelle oscillations

Reduction in component fatigue (yaw, foundation, multipliers, bearings, tower …) and preservation of their service life

Reduction in low frequency vibrations and therefore noise pollution

MEASUREMENT AND CORRECTION OF MASS BALANCE

Our methodology

- Mass balance of the rotor using test weights with LF vibration measurements before and during balancing

- Final correction of the mass unbalance by weight installation (depending on the type of machine)

Advantages of our solutions:

Aerodynamic and mass imbalance detection

Measurement of absolute and relative angular deviations with photometric measurement (accuracy of +/- 0.1 °)

Identification of the blades and assignment of the measured offsets to each of the blades which makes immediate correction possible

Acceptability of vibration measurements as validation of adjustment by turbine manufacturers

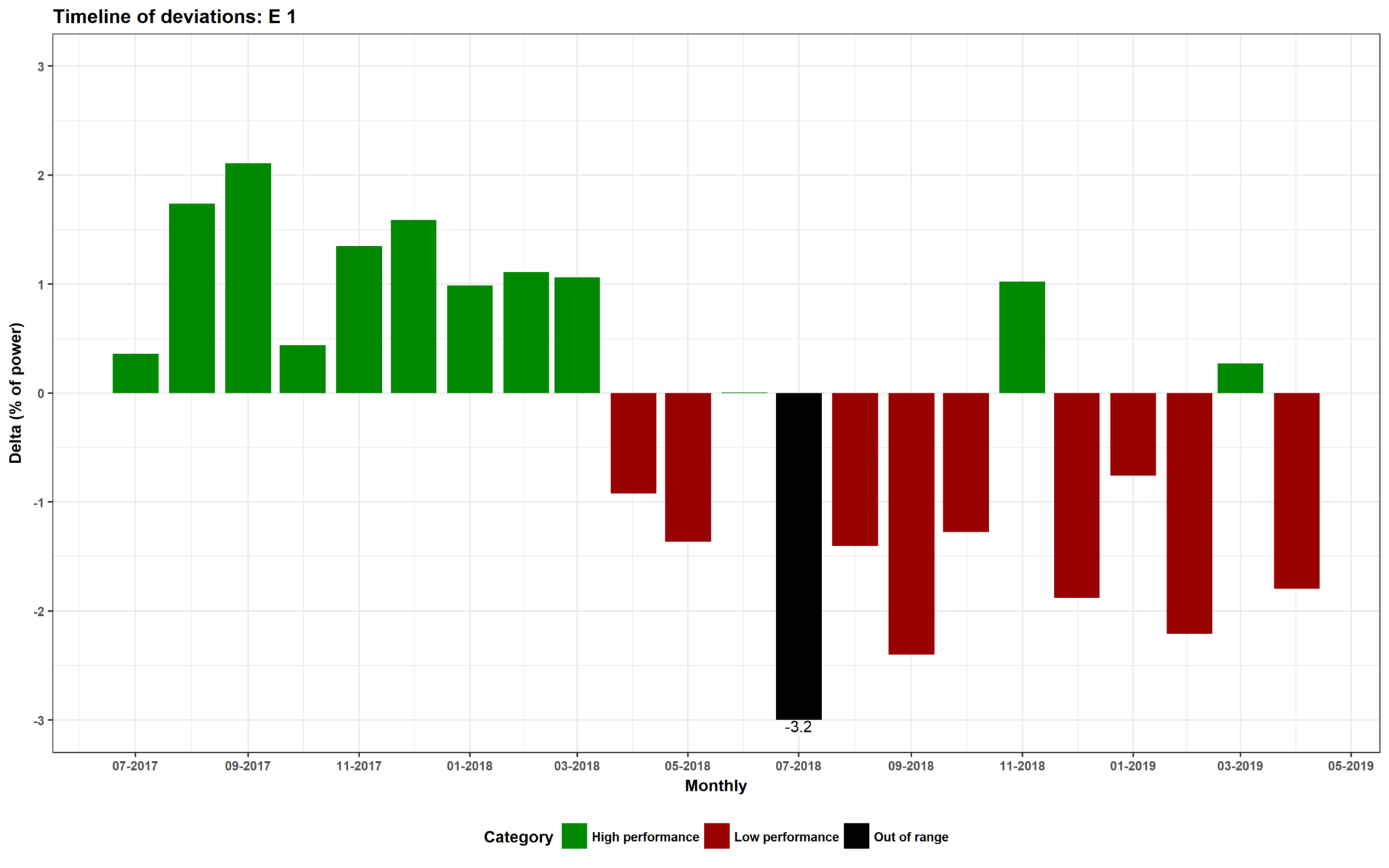

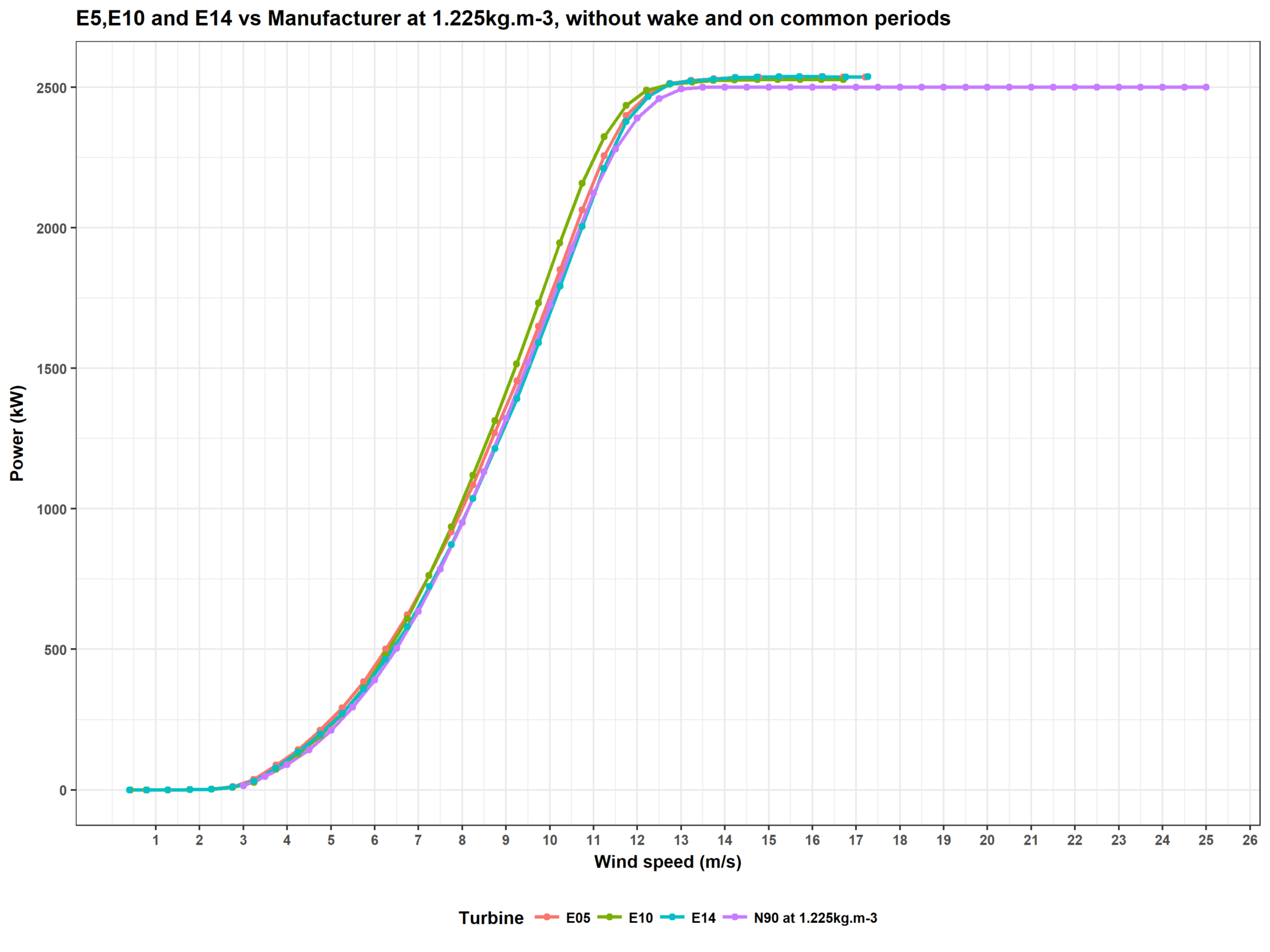

SCADA DATA ANALYSIS

In order to detect underperformance, anomalies and deviations of your assets, our experts have developed a reliable method for analyzing SCADA data, which is now widely recognized. This method improves the performance of your renewable energy parks (wind and photovoltaic).

Whether at key stages such as end of warranty or maintenance, or in case of suspected underperformance, our method can be used to analyze any complex mechanical system.

Our methodology: a two-step health check

Analyses based on power curves, pitch angles, rotor / generator rotation speeds, reactive power, …: comparison of wind turbines between them, evolution over time, …

VALIDATION OF RUN TEST

At the end of commissioning, 8.2 France offers an evaluation of the data from the functional tests.

In addition to this review of the “Run test” data, we recommend an Analysis of the SCADA data after 6 months of operation in order to quickly detect any deviations.

Wind Index

We can build several types of monthly wind indexes adjusted to the wind farms to monitor their performance.

optimized Wind index

- Initialization: 1 year of monthly availability and production data

- No additional data required monthly

- Monthly performance monitoring (based on independant weather data)

Standard Wind index

- Initialization: 1 year of 10-min SCADA data and knowledge of curtailment plans

- No additional data required monthly

- Monthly performance monitoring (based on independant weather data)

Advanced Wind index

- Initialization : 1 year of 10-min SCADA data and knowledge of curtailment plans

- Monthly index based on 10-min SCADA data

- Monthly performance monitoring

- Monthly balance of energy losses (curtailment, machine stops and grid failure)

- Detection of any inconsistencies between the theoretical curtailment plans and the plans actually implemented

If you have special needs, we can develop the solution you want.

PERFORMANCE CALCULATIONS AND AVAILABILITY

For a performance optimization of your photovoltaic farms in operation, we carry out independent reviews and calculate performance and availability ratios.

Advantages:

Production control and identification of critical points

Improved operating income through increased availability

OUR REFERENCES

KEY FIGURES FOR 8.2 FRANCE

8.2 FRANCE Measured 172 ROTORS FOR DEVIATIONS OF BLADE ANGLES

These last 3 years have shown that around 30% of rotors are affected by the effects of aerodynamic unbalance

They have put their trust in us